ABOUT PROJECT

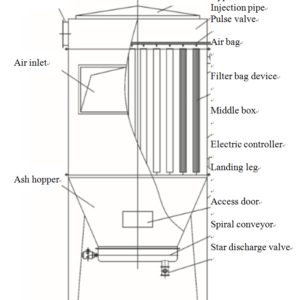

A lot of customers want to purchase high collection efficiency, simple maintenance, and inexpensive filter baghouse when they buy them. However, the filter bag is the most important part of the filter baghouse, its quality directly influences the collection efficiency and plays an important role in the work process in the baghouse.

Everspring makes a brief introduction: Condition dust bag can be divided into Normal and High Temperature. Normal temperature filter bag Normal temperature material of the bag is generally synthetic fibers, natural fibers, or glass fibers woven into cloth or felt, through subsequent calendering, singeing, stereotypes made into bags. It usually used temperature below 120 ℃. Requiring media with acid and durability under the circumstances , we often suggest in the polyester filter bag and polyester needle felt cloth.

1.PE needle punched felt and filter bag Polyester needle felt dust bag has a gap and high permeability, high dust collection efficiency, long life, and other advantages. Because of its moderate temperature levels, it instantly can reach 120 ℃. It also has an acid, alkali, and has a moderate external characteristic with very good abrasion resistance. So it is a breed felt type filter using a large amount.

2.Anti-static PE needle punched felt Anti-static PE needle punched felt with Acid resistance, weak base, wear resistance, corrosion resistance, good resilience, and poor conductive properties. Anti-static can be divided into anti-static grids, anti-static stripes. Polyester anti-static needle felt has a smooth surface, good wear resistance, high strength. Especially after the fight twist through higher strength, better abrasion resistance.

3.Coated needle punched felt Coated polyester needle felt features: air permeability, low resistance, good filtration efficiency, dust holding capacity. Polyester felt and PET film can be made into a variety of filter bags, cartridge filters, and they widely used in the field of treatment and recycling of industrial cement, metallurgy, food, paint, plastics, and other petrochemical fumes and dust particles.

4.Water repellent and Oil resistance needle punched felt Water repellent and Oil resistance needle punched felt can effectively prevent water and all kinds of oil were echoed penetration, compared with the general media, it not only has the water repellent and oil properties, but also in terms of dust also has anti-caking and ease of flaking. High-temperature needle felt and filter bag High temperature under 250 ℃, the main choice is graphite glass cloth. In some special cases, the choice is carbon fiber filter, etc.

1.Metamax punched needle felt and filter bag Metamax punched needle felt and filter bag with high temperature, high strength, resistance to acid corrosion, wear, bending, etc. After different surface chemical treatment and finishing technology , it also has easy cleaning, water, and oil repellent,anti-static, and other functions.

2.FMS filter bag FMS filter bag with high temperature, high strength, resistance to acid corrosion. , FMS filter bag after different surface chemical treatment and finishing technology, FMS filter bag also have easy cleaning, water and oil proof, anti-static characteristics; and a series of products for different temperature ranges. FMS filter bag compared to glass fiber filter, in wear resistance, fracture resistance, and peel strength is better. FMS filter bag compared with synthetic fiber filter temperature to overcome the fiber filter elongation, deformation, low temperature, poor corrosion resistance weaknesses; and FMS filter bag dimensional stability, strength better, and the price is lower than other high-temperature chemical fiber. FMS filter bag bags are widely used in iron and steel, metallurgy, chemicals, carbon black, building materials, electricity, and other departments.

3.Fiberglass needle punched felt and filter bag Fiberglass needle felt and filter bag is reasonable, better performance of high-temperature filter material. It not only has a fiberglass fabric temperature, corrosion resistance, dimensional stability, elongation minimal shrinkage, high strength advantage, and carpet fibers bearing a single fiber, three-dimensional microporous structure, high porosity, gas filtration resistance. It is a relatively high-speed, high-temperature filter material. Compared with other refractory fiber felt, it with low prices, low running resistance, high filtration precision, high temperature, and other special advantages. For iron and steel, metallurgy, carbon black, power generation, cement, chemical industry high-temperature gas filtration.

4.PPS Anti-acid needle punched felt and filter bag Working temperature 190 ℃, the short-time working temperature of 232 ℃, a melting point of 285 ℃. PPS fiber has the inherent strength retention and chemical resistance can maintain good filtration performance in harsh environments and it can achieve the desired service life. Infiltration fired boilers, waste incinerators, power plant fly ash dust processing in pulse cleaning dust collector, PPS filter felt is the ideal filter material.

Above all, each media has its own advantages, customers need to choose a suitable filter bag according to their own working conditions. Shanghai Everspring advises customers according to their own conditions and economic conditions to buy. We have a professional sales manager to give you pro suggestions.