Dust bag filter mechanism – – membrane fibre layer filter mechanism

Fourth, the filtration mechanism of the membrane fiber layer.

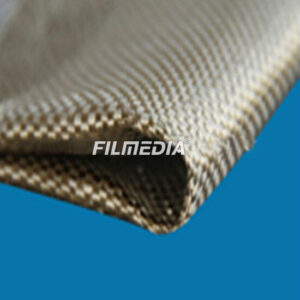

The membrane filter material is a microporous film layer of expanded polytetrafluoroethylene (ePTFE film) composed of hot pressing or adhesive bonding

High-end powder filter material made on the surface of conventional fiber layer filter material. The ePTFE membrane has a three-dimensional lattice structure, irregular pore shape, curved channel, pore diameter of only 0.2 ~ 3.0 mm, the porosity of up to 80 ~ 90%, which is the most reasonable fiber microporous structure to date. In terms of the filtering mechanism, in addition to the common effects of inertia, interception, diffusion, static electricity, etc., the mesh effect plays a major role. Using this microporous film instead of the primary powder layer, even in the early stages of filtration, fine dust particles are difficult to penetrate the fiber layer, achieving true surface filtration. Its filtration efficiency can reach 99.99%, which is an order of magnitude greater than that of conventional filmless filter materials. The ePTFE membrane is non-sticky, has low surface tension, and has excellent cleaning performance.

Post-processing measures such as calendering, charring, and surface coating of conventional fiber layer filter material, as well as the development of high-density surface layer gradient fiber layer filter material, are designed to improve the surface micropore structure of the fiber layer filter and minimize the dust deposited in the fiber layer for conversion from bulk filtration to surface filtration, but their effect is not yet as good as that of the membrane filter material.