Dust bag filter mechanism – – fibre layer filter mechanism

Secondly, the filtering mechanism of the fiber layer.

The fiber layer is a porous aggregate composed of many individual fibers or threads arranged ina given structure. In addition to the inertia effect, interception effect, diffusion effect, electrostatic effect, and gravity effect mentioned above, the filtering mechanism of the fiber layer also has a mesh effect.

When the airflow containing dust passes through the fiber layer, the dust in the gas with a particle size larger than the fibers, the pores between the wires, or the pores between the dust are collected by detection, which is called the detection effect.

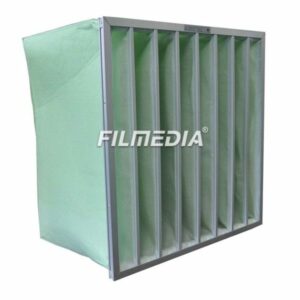

In the field of industrial dust removal, there are two types of fiber layer filter materials commonly used, woven organic fabric and needle felt. The structure and manufacturing process of the two types of fibrous layer filter materials are not the same, and the initial filtration mechanism is also different.

Filtration mechanism of the woven fiber layer.

The woven fabric is a set of fibers with a flat two-dimensional structure in which the fibers are spun into thread and then woven into various textures. The fiber layer of the woven fabric is thin, generally less than 1 mm, the fibers are tightly bonded and the pores are small, the pores crossed between the lines are large, the channels are straight, the diameter of the pores is about 30 ~ 60 mm, and the overall vacuum ratio is about 35% ~ 50%. Between them, the gap between the lines that actually plays the role of ventilation and filtration is only 30-40%. When the airflow containing dust passes through the fiber layer, the dust is mainly affected by the inertial effect, the interception effect, the diffusion effect, and the detection effect. Some of the dust particles adhere to the surface of the fiber, become trapped and accumulated, and then bind to form a powder layer, and some fine dust particles penetrate the fiber layer. During dust cleaning and regeneration, ash accumulation is easy to loosen and disperse due to the straightness of the pores in the fiber layer. From the analysis of the filtration mechanism, although the initial filtration of the woven fabric fiber layer has somebody’s filtration function, it is closer to the surface filtration function.

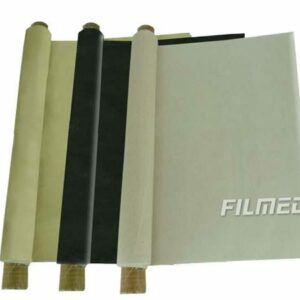

Mechanism of filtration of the needle felt fiber layer

Acupuncture felt is a three-dimensional spatial structure fiber assembly made by mechanical or chemical winding and tangling of fibers, or by rolling fibers into a network (fleece), and then using needle punching (or spinning) to tangle.

The needle felt fiber layer is relatively thick, generally 1.5 to 2.5 mm thick, forming an empty structure between the fibers, the channels are tortuous and evenly distributed, the pore size is approximately 10 ~ 40 mm, and porosity can reach 70 ~ 80%. When the airflow containing dust passes through the fiber layer, the dust is mainly affected by the combined effects of the inertial effect, the interception effect, the diffusion effect, and the detection effect. Some of the dust particles are trapped by the fibers, and some of the dust particles penetrate the pores within the fiber layer, forming a body that joins with the fibers, then expands to the surface to form a dust layer, and a small amount of fine dust penetrates the fiber layer. During dust cleaning and regeneration, due to twists and turns in the fiber layer, it is not easy to escape dust accumulation. From the analysis of the filtering mechanism, the filtering mechanism of the initial needle perforated felt fiber layer is similar to that of the air filter, and the filter of the main body is the main body. With the establishment of the surface dust layer, the transition to the surface filter gradually. Acupuncture felt is a three-dimensional spatial structure fiber assembly made by mechanical or chemical winding and tangling of fibers, or by rolling fibers into a network (fleece), and then using needle punching (or spinning) to tangle.

The needle felt fiber layer is relatively thick, generally 1.5 to 2.5 mm thick, forming an empty structure between the fibers, the channels are tortuous and evenly distributed, the pore size is approximately 10 ~ 40 mm, and porosity can reach 70 ~ 80%. When the airflow containing dust passes through the fiber layer, the dust is mainly affected by the combined effects of the inertial effect, the interception effect, the diffusion effect, and the detection effect. Some of the dust particles are trapped by the fibers, and some of the dust particles penetrate the pores within the fiber layer, forming a body that joins with the fibers, then expands to the surface to form a dust layer, and a small amount of fine dust penetrates the fiber layer. During dust cleaning and regeneration, due to twists and turns in the fiber layer, it is not easy to escape dust accumulation. From the analysis of the filtering mechanism, the filtering mechanism of the initial needle perforated felt fiber layer is similar to that of the air filter, and the filter of the main body is the main body. With the establishment of the surface dust layer, the transition to the surface filter gradually.