The advantages and principles of printing the skeleton of the dust collector

The skeleton of the dust collector is used as the skeleton of the bag dust collector. The importance of their quality is obvious. So how can we improve the performance of the dust removal frame?

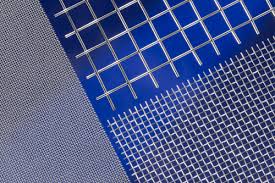

Electrostatic spray painting of the dust removal frame is a good protection measure, which is much better than the general galvanized dust removal frame.

The galvanized dust removal frame is easily affected by environmental factors, thus corroding, directly reducing the life of the bag filter and dust bag. The adhesion and mechanical strength of the dust removal frame will increase after printing. The dust removal frame after printing can withstand high temperatures. Due to the spray paint, the surface is smooth, leading to installation.

The principle of the inkjet dust removal frame: the use of corona discharge to make the powder coating adsorb on the workpiece. The process is: the powder coating is sent to the spray from the compressed gas powder supply system, and the high voltage generated by the high voltage electrostatic generator is added to the spray front. Due to corona discharge, dense electrical charges are generated near it. When the powder is sprayed from the nozzle, charged paint particles are formed and subjected to an electrostatic force.