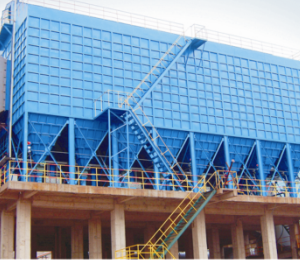

Precautions for the skeleton of the dust collector at the beginning of the operation

One month after the pulse dust collector starts, the operation time of the pulse dust collector is the initial operation stage of the pulse dust collector. This month is the period when the bag filter is most prone to malfunction. For example, the operators of the dust collector are not experts in the technical process, and the selection and installation of the dust bag are unreasonable. Equipment purification problems, etc. Only when problems are eliminated in time with full attention can the goal of stable operation be achieved.

Processing air volume: to stabilize the pressure loss from the dust removal bag, the method of greatly increasing the volume of processing air during operation is often used to allow the gas to flow through the dust removal bag smoothly. At this time, if the fan motor is overloaded, the total valve can be used to adjust the air volume. Because this situation can take a few minutes as quickly as possible and take several days to return to normal. It is therefore best for the dust collector in the workshop to look at the pressure gauge at the beginning. The corresponding air volume value can also be calculated from the ammeter reading on the control panel.

Temperature setting: it is easier to use a bag filter to process flue gas dust at room temperature, but when gas is processed at high temperature and high humidity, initial operation, if not preheated, the dust bag is easy to wet, and the filter space of the needle felt filter material is easy to lock. Besides, if the dust bag is not completely dry, condensation will often occur. It is difficult to accurately predict the dew point of the bag filter, so attention should be paid to the clogging of filter holes and corrosion of the inner surface of the dust collector housing due to condensation.

The problem of dust removal efficiency: after the dust removal cloth bag forms a dust absorption layer, the dust removal efficiency of the cloth bag is the highest at this time. At this time, the bag filter is in an unstable state due to the increase in the initial processing air volume. Therefore, it is best to measure the dust removal efficiency several days or a month after the operation. In a steady-state, the dust removal efficiency of low-concentration dust with very fine particles should generally be above 99.9%.

The dust discharge and dust accumulated in the ash hopper can be discharged automatically or manually but must be discharged in the prescribed order. In the initial stage of operation, the powder is often not discharged for one or several days. The powder adheres to the dust bag until it reaches the maximum dust holding capacity of the dust collector, and then is discharged in order. If the dust discharge cycle is incorrect, a stable operating system cannot be formed. Generally, when the amount of dust recovered is too much, it is mainly because the default value originally designed is not accurate. If the default amount of dust is not reached, the dust must be continuously extracted at the beginning to control the amount of dust recovered.