Introduction of Spunbond Nonwoven

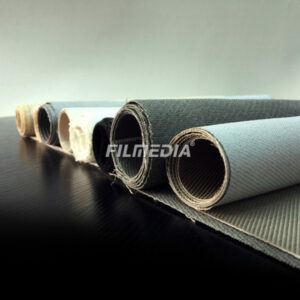

Spunbond nonwoven fabric, the main materials are polyester and polypropylene, high strength and high temperature resistance.

Definition:

After the polymer is extruded and stretched to form a continuous filament, the filament is laid into a net, which is then bonded by itself, heat, chemical or mechanical means to make the net non-woven.

Characteristic:

High temperature resistance, low temperature resistance (polypropylene fiber can be used in 150 ℃ environment for a long time, polyester can be used in 260 ℃ environment for a long time), aging resistance, UV resistance, high elongation, good stability and permeability, corrosion resistance, sound insulation, moth proof and non-toxic.

Main purpose:

The main materials of spunbond nonwovens are polyester and polypropylene.

The main products of spunbond nonwovens are polypropylene, polyester (long fiber, short fiber) nonwovens. The most common and most commonly used applications are nonwovens bags, nonwovens packaging, etc.; the identification of spunbond nonwovens is relatively easy, generally two-way fastness is good, and generally the rolling point of spunbond nonwovens is diamond shaped.

At the application level, it can also be used to make flower packing cloth, luggage cloth, etc., with the characteristics of wear-resistant, strong handle, etc., making it the best choice to make such products.