ES-FB760W-TFI

Technical Specification Sheet

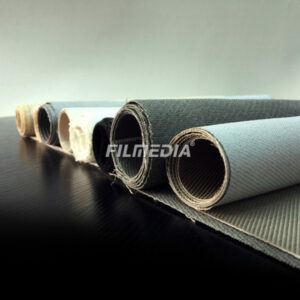

| Product Name | Fiberglass woven cloth 760 gsm | |

| Product Code | ES-FB760W-TFI | |

| Physical properties | ||

| Weave method | Double Twill | |

| Thickness | 0.75±0.08 | |

| Weight | g/m² | 760±10 |

| Width | m | ≤2.20M |

| Loss on Ignition (%) | ≥10 | |

| Chemical Finish | Teflon, PTFE membrane finish | |

| Air Permeability (L/m².S@200Pa) | 310±25 | |

| Density (ROOT/INCH) |

Warp | 46±2 |

| Weft | 39±2 | |

| Tensile Strength (N/25mm) |

Warp | ≥2200 |

| Weft | ≥2000 | |

| Temperature | ||

| Continues temperature | C° | 260 |

| Instant temperature | C° | 280 |

ES-FB760W-TFM

Technical Specification Sheet

| Product Name | Fiberglass woven cloth 760 gsm with PTFE membrane | |

| Product Code | ES-FB760W-TFM | |

| Physical properties | ||

| Weave method | Double Twill | |

| Thickness | 0.75±0.08 | |

| Weight | g/m² | 760±10 |

| Width | m | ≤2.20M |

| Loss on Ignition (%) | ≥10 | |

| Chemical Finish | Teflon, PTFE Lamination | |

| Air Permeability (L/m².S@200Pa) | 50±15 | |

| Density (ROOT/INCH) |

Warp | 46±2 |

| Weft | 39±2 | |

| Tensile Strength (N/25mm) |

Warp | ≥2200 |

| Weft | ≥2000 | |

| Temperature | ||

| Continues temperature | C° | 260 |

| Instant temperature | C° | 280 |

The above mentioned data have been determined according to the averages obtained from a series of typical results by our lab and are intended just for reference. The technical information is subject to changes, usual tolerances apply.

Applications details

| Cement Plant | |||||||

| Product Specification sheets | |||||||

| Finish | Weave Pattern | Weight(g/m2) | Air Permeability(cm3/cm2·s@127pa) | Loss on lgnition (%) |

Tensile Strength(N/25mm) | Running Temperature (°C) |

|

| Warp | Weft | ||||||

| PTFE Finished + Membrane | Double Twill | 750±25 | 2—5 | >10 | >2400 | >2000 | ≦260 |

| Acid-Resistant Finished + Membrane | 1/3 Twill | 340±15 | 2—5 | >10 | >1300 | >800 | ≦260 |

| Steel Plant | |||||||

| Product Specification sheets | |||||||

| Finish | Weave Pattern | Weight(g/m2) | Air Permeability(cm3/cm2·s@127pa) | Loss on lgnition (%) |

Tensile Strength(N/25mm) | Running Temperature (°C) |

|

| Warp | Weft | ||||||

| PTFE Finished + Membrane | Double Twill | 750±25 | 2—5 | >10 | >2400 | >2000 | ≦260 |

| Acid-Resistant Finished + Membrane | Double Twill | 750±25 | 2—5 | >10 | >2400 | >2000 | ≦260 |

| Acid-Resistant Finished + Membrane | 1/3 Twill | 340±15 | 2—5 | >10 | >1300 | >800 | ≦260 |

| Graphite Finished + Membrane | 2/5 Satin | 550±15 | 2—5 | >3 | >2000 | >2000 | ≦260 |

| Graphite Finished + Membrane | 2/5 Satin | 550±15 | 30—50 | >1.5 | >2000 | >2000 | ≦260 |

| Coal-fired Boiler | |||||||

| Product Specification sheets | |||||||

| Finish | Weave Pattern | Weight(g/m2) | Air Permeability(cm3/cm2·s@127pa) | Loss on lgnition (%) |

Tensile Strength (N/25mm) |

Running Temperature (°C) |

|

| Warp | Weft | ||||||

| Acid-Resistant Finished + Membrane | Double Twill | 750±25 | 2—5 | >10 | >2400 | >2000 | ≦260 |

| Ferroalloys | |||||||

| Product Specification sheets | |||||||

| Finish | Weave Pattern | Weight(g/m2) | Air Permeability(cm3/cm2·s@127pa) | Loss on lgnition (%) |

Tensile Strength(N/25mm) | Running Temperature (°C) |

|

| Warp | Weft | ||||||

| Acid-Resistant Finished + Membrane | 1/3 Twill | 500±15 | 2—5 | >10 | >2000 | >1200 | ≦260 |

| Acid-Resistant Finished + Membrane | 1/3 Twill | 340±15 | 2—5 | >10 | >1300 | >800 | ≦260 |

| Graphite Finished + Membrane | 2/5 Satin | 550±15 | 2—5 | >3 | >2000 | >2000 | ≦260 |

| Graphite Finished + Membrane | 2/5 Satin | 550±15 | 30—50 | >1.5 | >2000 | >2000 | ≦260 |

| Biomass Power Generation | |||||||

| Product Specification sheets | |||||||

| Finish | Weave Pattern | Weight(g/m2) | Air Permeability(cm3/cm2·s@127pa) | Loss on lgnition (%) |

Tensile Strength(N/25mm) | Running Temperature (°C) |

|

| Warp | Weft | ||||||

| PTFE Finished + Membrane | Double Twill | 750±25 | 2—5 | >10 | >2400 | >2000 | ≦260 |

| Acid-Resistant Finished + Membrane | Double Twill | 750±25 | 2—5 | >10 | >2400 | >2000 | ≦260 |

| Chemical Plants | |||||||

| Product Specification sheets | |||||||

| Finish | Weave Pattern | Weight(g/m2) | Air Permeability(cm3/cm2·s@127pa) | Loss on lgnition (%) |

Tensile Strength (N/25mm) |

Running Temperature (°C) |

|

| Warp | Weft | ||||||

| PTFE Finished + Membrane | Double Twill | 750±25 | 2—5 | >10 | >2400 | >2000 | ≦260 |

| Carbon Black | |||||||

| Product Specification sheets | |||||||

| Finish | Weave Pattern | Weight(g/m2) | Air Permeability(cm3/cm2·s@127pa) | Loss on lgnition (%) |

Tensile Strength(N/25mm) | Running Temperature (°C) |

|

| Warp | Weft | ||||||

| PTFE Graphite Silicone Finished | 1/3 Twill | 470±15 | 15—30 | >3 | >2000 | >1000 | ≦260 |

| Acid-Resistant Finished + Membrane | 1/3 Twill | 500±15 | 2—5 | >10 | >2000 | >1200 | ≦260 |

There are no reviews yet.