Optional standard micron:

| Grade | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | |||||||||||||

| micron(μm) | 0.5 | 1 | 5 | 10 | 25 | 50 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 800 |

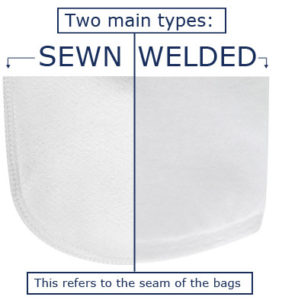

Optional Felt Bag Seam Styles:

Sewn Details:

1. Industry-standard make

2. 5 needle suture

3. Strong construction can afford heavy dirt holding capacity

Welded

1. No needle holes

2. No thread contamination

3. Precision bonded cutting of the fabric edges

4. Maintain same efficiency as filter media

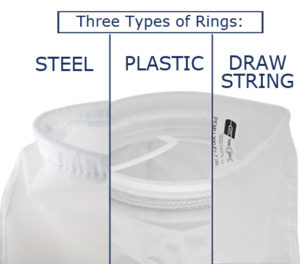

Optional Rings

Steel Ring

- Galvanized steel (stainless steel option)

- Sewn into the top of the bag

- Cotton handle is standard with steel ring configuration

- Designed to gasket as well as support and secure filter bag when placed into housing

Plastic Ring

- Molded plastic with built-in handle makes installation and disposal faster, cleaner and less expensive

- Just drop into housing and push down

- Smooth plastic designs prevent build-up of contaminants around header

- Collar is sewn or welded into place to ensure that plastic media remain firmly intact

DrawString

- Adjustable top diameter to make easy tie on to piping

- Great for gravity feed applications

- Easy disposal

- Economical filter applications

4 types of standard liquid filter bag: (accept customization)

| Model | Filter area (m²/ pcs) |

Volume (L) | Diameter | Length | ||

| cm | inch | cm | inch | |||

| Type 1 | 0.19 | 7.9 | 17.8 | 7 | 40.65 | 16 |

| Type 2 | 0.41 | 17.3 | 17.8 | 7 | 81.3 | 32 |

| Type 3 | 0.05 | 1.4 | 10.2 | 4 | 20.9 | 8.25 |

| Type 4 | 0.09 | 2.5 | 10.2 | 4 | 35.5 | 14 |

Chemical properties Comparison:

| Fabric | Abrasion resistance | Anti weak acid | Anti strong acid | Anti weak alkali | Anti strong alkali | Temperature (℃) |

| PE (polyester) | Very good | Very good | Good | Good | Poor | 130-150 |

| PP (polypropylene) | Very good | Excellent | Excellent | Excellent | Excellent | 80-100 |

| PA (nylon) | Excellent | Normal | Poor | Excellent | Excellent | 90-150 |

Please inform us the detail of the environment

Different environments decide different filter bags. In order to ensure that the accident will not happen to choose the most suitable filter bag for the environment is particularly important. Temperature, humidity, PH, gas composition and so forth, the more detail the better. Our client manager prepared a questionnaire, just fill it then we can give you the suitable products.

Ensure standardized installation

Meanwhile, the installation process is also particularly important, non-standard installation is a major cause of accidents. Be sure to check the situation after the filter bags installed.

There are no reviews yet.