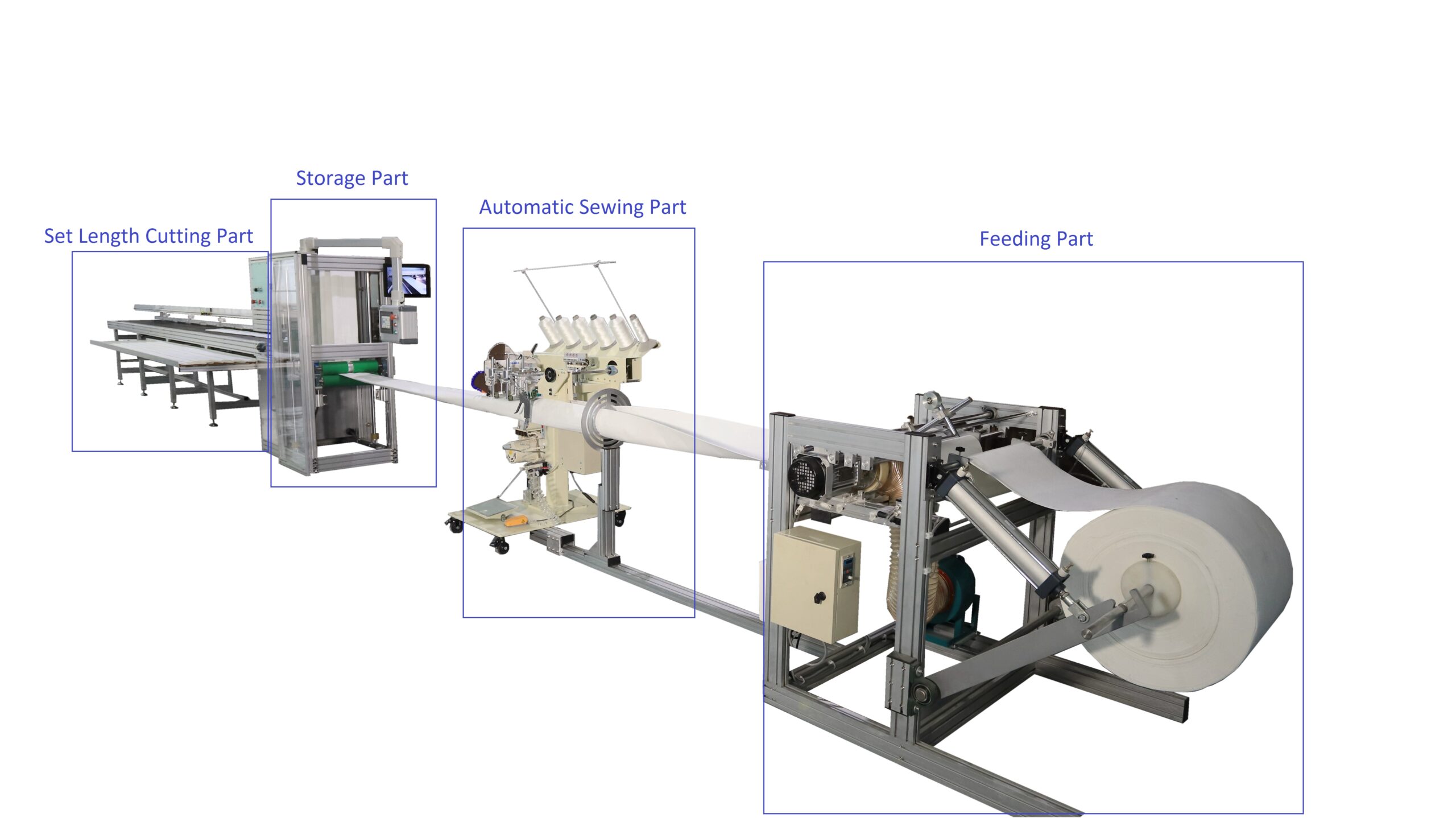

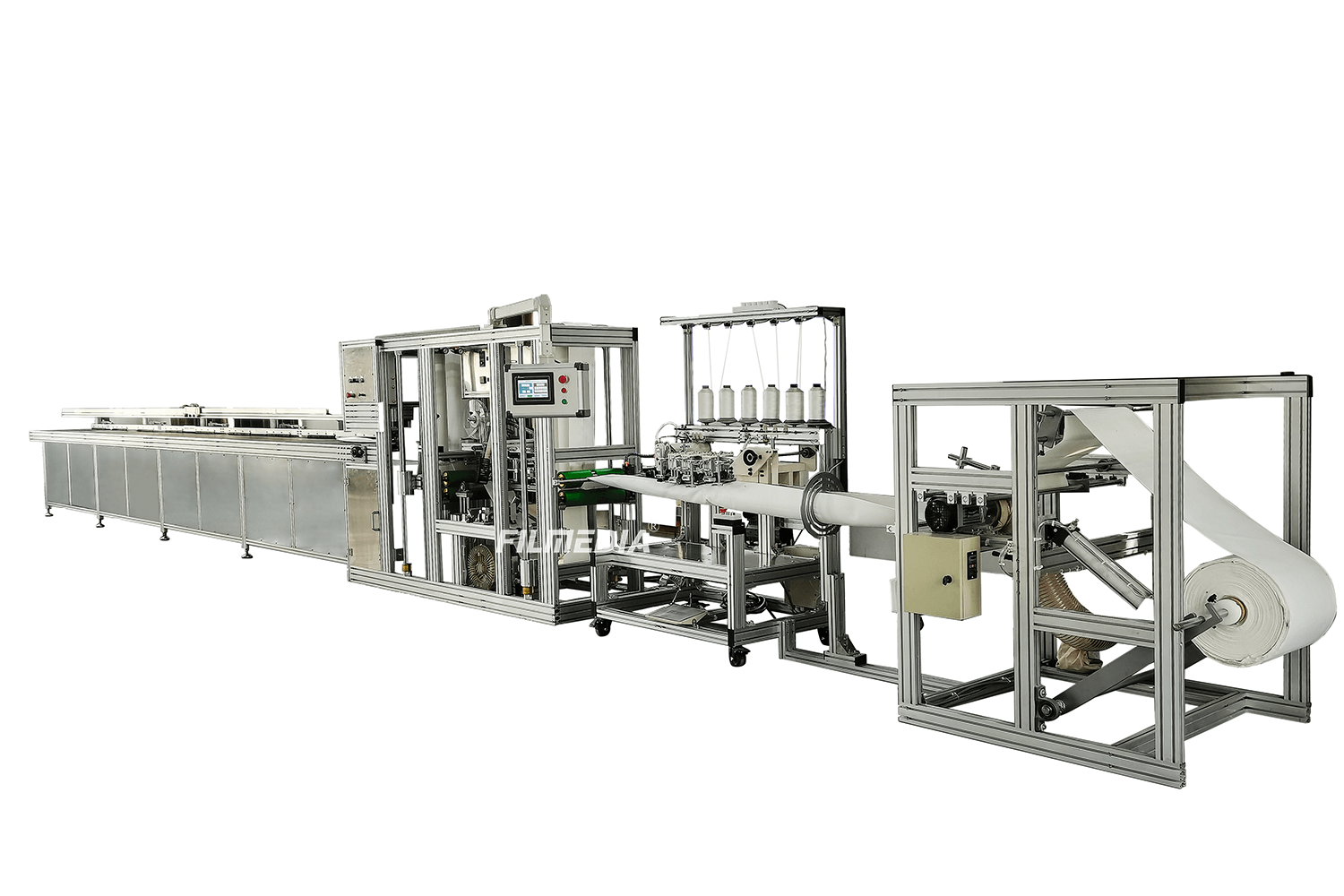

The Advantage of Our Automatic Sewing Line for Filter Bag

- The whole line can meet the production requirements of various processes such as sewing, gluing, hot welding, and PTFE taping.

- This line is equipped with a brand-new fabric forming mold, which is suitable for sewing or welding of various specifications of filter bag body, with good forming effect and stable seam width.

- The sewing machine includes an automatic stop device for automatic detection of broken threads, and automatic stop when abnormal thread breaks.

- Adopt positioning device, precise film location; linkage work, automatic film application.

- Special heating device, the temperature can reach 700℃, the temperature fluctuates ±2℃, which can be applied to the film sealing of pure PTFE filter bag.

- This line includes a stripping machine and a film debris collection device, and no problem with membrane material hot welding.

- This line’s work roller is covered with low-hardness polyurethane, which has good flexibility and is not easy to damage the PTFE membrane on the surface of the filter material.

- The main body adopts aluminum profile structure, the installation is firm and the operation is stable.

- This whole line is equipped with high-power cutter motors and alloy steel blades, which can easily cut PTFE and woven fiberglass filter bags.

- Choose programmable control system, servo control system, frequency conversion control system, so the equipment failure rate is extremely low.

Basic Parameters

- Power: 2.0kw.

- Rated voltage: AC380V, rated frequency: 50~60HZ.

- Dimensions: 16000×800×1800mm.

- Sewing speed: 0~10m/min,

Gluing speed: 0~10m/min,

Hot welding speed: 0~12m/min,

PTFE taping speed: 0~10m/min. - Compressed air pressure: 4~5kg/cm².

There are no reviews yet.