Product quality and compliance with dust emission limits are core requirements for dedusting in the cement, gypsum, and lime industry. The choice of filter media is of paramount importance in cement kilns where there are high NOx levels due to high combustion temperatures. The Everspring filter media range offers for each process in the cement, gypsum, and lime industry technically sophisticated solutions.

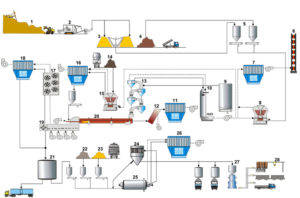

| 1 | Quarry | 2 | Crusher plant | 3 | Raw material homogenization | 4 | Aggregates |

| 5 | Raw mill feeding silo | 6 | Main stack | 7 | Bag filter for kiln-/raw mill | 8 | Vertical raw mill |

| 9 | Raw material feeding silo | 10 | Gas conditioning tower | 11 | Bag filter for alkali bypass | 12 | Bypass mixing chamber |

| 13 | Cyclone pre-heater | 14 | Raw coal | 15 | Vertical coal grinding mill | 16 | Bag filter for coal grinding plant |

| 17 | Tubular cooler | 18 | Bag filter for clinker cooler | 19 | Clinker cooler | 20 | Rotary kiln |

| 21 | Clinker silo | 22 | Gypsum | 23 | Minerals | 24 | Separator |

| 25 | Cement finish mill | 26 | Bag filter for cement finish mill | 27 | Packaging plant | 28 | Palletization plant |

Typical Operating Conditions:

| Continue Temperature(°C/℉): | 200/392-250/482 |

| Peak Temperature: : | Orientation to the maximum peak temperature of the fibre polymers used |

| Dust: | Cement, clinker, coal, gypsum, lime, raw meal |

| Dust Properties: | Agglomerating, abrasive, explosive |

| Dust Source: | Blast furnace, chlorine bypass, clinker cooler, coal grinding, mill, rotary kiln, spray dryer, silo, transfer stations |

| Harmful Gases: | H2O, NOx, SOx, HCl |

| Cleaning Process: | Pulse jet, reverse air |

| Fuels: | Natural gas, coal, oil, secondary fuels |

Specific Requirements for Filter Media in the Cement, Gypsum and Lime Industry:

- High abrasion resistance

- Discharge of electrostatic charges

- High chemical resistance

Four kinds of products can be used in the cement plant.

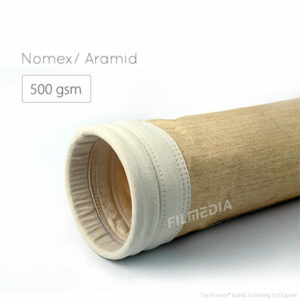

P84, PTFE Fiberglass, and Nomex.

There are no reviews yet.