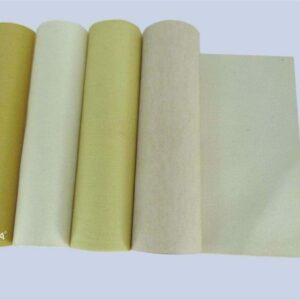

PPS (Ryton) Needle Felt

Our capacity:15000 square meters per day (standard PPS product)

Diameter & Length: Accept customization

PPS has good chemical stability, a wide temperature range, resistance to atmospheric aging, better radiation resistance, low permeability, and many other performance advantages. Despite PPS having superior performance, the high price of PPS is its large-scale promotion of the obstacle.

Finish-treatment: Calendering, Heat setting, Singeing

Description

We now mainly have three categories of PPS woven fabrics:

1. PPS filament, thickness 2.2-0.3mm, weight 1150-200g

2. PPS short fiber, thickness 2.2-0.3mm, weight 1150-200g

3. PPS monofilament, thickness 0.8-0.15mm, weight 550g-80g

Features of PPS (Ryton) Needle Felt:

1. Excellent Anti-Acid And Anti-Alkali

2. Anti-High Temperature:190-220°C/374-428°F

3. High-efficiency filtration

4. Suitable for the filtration of sulfur fumes or sulfur oxides in fuel

5. Very easy to be oxidized in sunshine

6. Suitable for high humidity, high concentration, and flue dust containing chemical ingredients

7. Can be customized

Notice: Common brands of PPS include Ryton®and Procon® and belong to Philip Company.

Physical and Chemical Properties of PPS (Ryton) Needle Felt: (Customization is accepted in terms of feature and size)

| Weight(gsm) | The three options mentioned above | |

| Thickness(mm) | The three options mentioned above | |

| Width(m) | The three options mentioned above | |

| Finish treatment | Singeing, Calendering, Heat setting | |

| Air permeability(L/m2.s) | 200-300 | |

| Tensile strength(N/5 cm) | warp | ≥1100 |

| weft | ≥1500 | |

| Tensile elongation(%) | warp | ≤15 |

| weft | ≤20 | |

| Heat shrinkage(%) | warp | ≤1.5 |

| weft | ≤1.0 | |

| Temperature(°C/°F) | Continue | 190/374 |

| Instant | 220/428 | |

| Anti-acid | Good | |

| Anti-alkali | Excellent | |

| Anti-abrasion | Excellent | |

| Hydrolysis stability | Middle | |

Option 2

We also supply a new material that can replace the PPS needle felt. It has the characteristics of the PPS needle felt, but the continued temperature can be up to 250℃. The following are the specification for the new products.

| Weight(gsm) | 810 | ||

| Thickness(mm) | 0.75 | ||

| Air permeability(cm³/cm²/s) | 2-4 | ||

| Tensile strength(N/25mm) | warp | 2400 | |

| weft | 2800 | ||

| Temperature(°C/°F) | Continue | .260/500 | |

| Instant | 300/572 | ||

| Anti-acid | Excellent | ||

| Anti-alkali | Excellent | ||