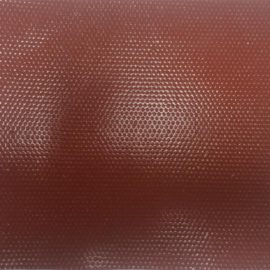

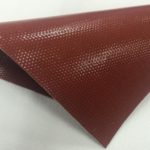

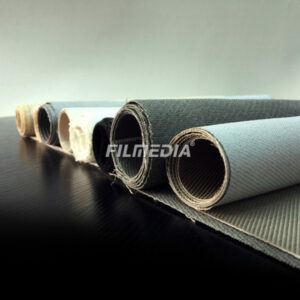

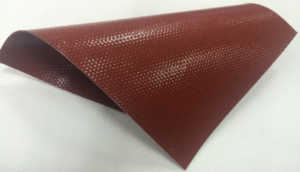

Silicone Coated Fabric

Product Name : SILICONE COATED FABRIC

Product Code : ES-SCCF1500

ES-SCCF1500 is a double-sided silicone tape coated with a reusable silicone compound and heat resistive silicone adhesive. It is specifically designed to temporarily fix FPC or tiny components to carrier jig during SMT processing. Easy-to-clean silicone coated fabric is cost-effective due to its reuse even in high temperature environments.

Description

Physical Properties:

- Thickness : 1 mm

- Total weight (g/m2) :1500

- Weight of fiberglass fabric (g/m2) : 852

- Double side with silicone coated

- Tensile strength (N/5 cm ) Warp : ≥5500 Weft : ≥ 5000

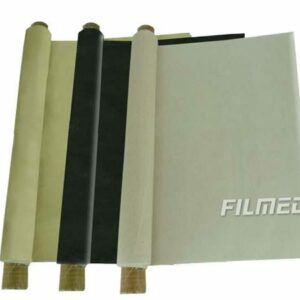

- Width ( m ) : 1.5

- Operation temperature range ( ℃ ) : – 50 ~ 250

Features & Benefits :

- Excellent dimensional stability at high temperature

- (No distortion, shrinkage/expansion at 260℃ continuous usage condition.)

- Superior adhesion and holding power of silicone adhesive

- No adhesive residue after removal

- Longer life time of silicone resin side

- Easy cleaning using cleaning roller allows extended lifetime

- Good surface flatness allows the whole area of FPC to be fixed

- Adhesion level of silicone compound can be controlled for customer’s requirement

(Low – Moderate – Standard – High – High2 – High3)

- Excellent cut & die-cut properties

- Easy fixing and easy removal

- Provides flexibility for carrier design

Applications

- SMT Process

– Reflow Soldering of FPC, Thin Rigid PCB & Rigid-flex PCB, etc

2.Assembly Process (including curing, wire bonding, etc)

– MEMS Microphone

– Camera Module, Vibration Motor

– Wireless LAN Module, GPS Module

– RF Module

– Accelerometer Sensor, Gyro Sensor

– Humidity Sensor, Temperature Sensor, etc.

– Flip Chip Mounting Process

– Flip Chip Mounting

3.LED Packaging Process

– LED Chip Bonding, Wire Bonding, Molding, etc.

4.Display Panel Process

– Carrier of LCD Panel, OLED Panel

– Temporary Fixing of Touch Panel

– Detaching Protection Films from LCD Panel

or Polarizing Film

– Probe Station

– Fixing of Electrostatic Chuck

5.Substrate Manufacturing Process

– Dicing of LTCC, CSP or Inductor substrates

– MLCC Termination

– Micro-polishing of Thin Package Substrate