Woven Satin Filter Bag

Woven satin filter bags are characterized by anti-collapse rings sewn onto the bag body to prevent the bag from collapsing when the flow is reversed. The majority of satin bags are 5”, 8” or11.5” diameter and may be as long as 35′-40′ overall. These bags are installed under tension to minimize movement. Sonic horns may also be used to assist dust release.

Finish: laminated and non- laminated treatment. And both have silicone oil treatment and graphitization treatments.

Free samples will be provided.

Description

Woven satin filter bags are made from woven fabrics including fiberglass, however, felts are also used with cake release surfaces and chemical treatments. Felts offer greater flow at comparable efficiencies or higher efficiencies at comparable flows.

Specifications:

| Weight gsm | Working temperature ℃ | Max temperature ℃ | Texture |

| 350-800 | 260 | 280-300 | sloping weave, plain weave, satin, twill |

Advantages:

- Good resistance to acid

- Performs best at high temperature

- Increase in airflow

- Decrease in pressure drop

- Reduces maintenance and downtime

About the treatment:

The key to the optimum performance of the fiberglass woven satin filter bags lies in the application of the finish treatment. Without the finish treatment, the glass filaments in filtration fabrics are broken through abrasion caused by dust particles or chemical attacks from the gas stream. Woven cloth satin filter bag usually adopts laminating or non-non- laminated treatment, silicone oil treatment, and graphitization treatments.

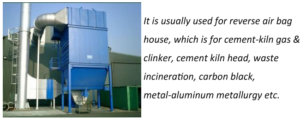

Application: