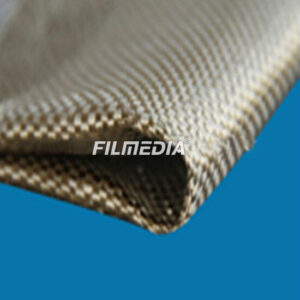

Fabric filter The staggered arrangement of the warp and weft of the fabric filter material is called the weave of the fabric. The basic organization has three original organizations: plain weave, twill weave and forged weave. Plain weave: Plain weave is the simplest weave in the fabric. The warp and weft can form a complete […]…

Polyester anti-static needle felt and polyester coated needle felt Polyester anti-static needle felt: Anti-static needle felt is a functional filter material made of composite fabrics such as conductive fibers in the warp of the filter material base cloth or mixed with conductive fibers in the fiber web, which has the characteristics of explosion-proof. Use occasion: […]…

The harm of static electricity in the filter system In air filtration, especially in industrial air filtration systems, filter materials are mainly used for continuous operation of dust collection systems and purification of smoke and steam, etc. And their workload is relatively large. Dust particles have dispersibility and suspension. The dispersibility makes it have a large contact […]…

Filtering method and precautions of dust bag Filtration methods are mainly divided into internal filtration and external filtration: 1. Internal filter type dust bag: After the dust-containing gas is filtered by the inner surface of the filter bag, the dust is blocked on the inner surface of the filter bag. This filtering method is called […]…

Influence of flue gas characteristics on filter bag When the bag filter is used in the chemical industry, coal-fired power plants, steel and non-ferrous metals and other industries, the characteristics of the flue gas are complicated because of the process. When the selection of filter material is not fully considered, the filter bag will quickly […]…

Maintenance of dust removal air source system of dust collector Control of cleaning pressure: During operation, the pressure of the cleaning gas source is controlled between 0.08-0.1MPa, so that it can reduce the damage to the filter bag caused by the back-blowing and cleaning without affecting the effect of soot-blowing. The adjustment of the setting […]…

Filtration mechanism of membrane filter The membrane-coated filter material is a composite of a microporous membrane made of dispersed polytetrafluoroethylene resin and various substrates. The biggest feature of the filter material is surface filtration, which can improve filtration efficiency and improve the problems of increasing filtration pressure and high concentration of fine dust emissions that […]…

Air inlet method of bag filter The air inlet mode of the bag filter can be divided into three modes: upper air inlet, lower air inlet and side air inlet. Upper air inlet method Dust-laden gas enters from the top of the filter bag and exhausts from the bottom. The dust sedimentation direction in the dust-containing […]…

Applicable working conditions of pre-sprayed filter bag 1、The dusty gas contains liquid viscous substances such as oil fume. This sticky substance will not corrode the filter bag. Due to the high adhesion, it mixes with the dust in the gas to form a mud-like substance, which blocks the pores of the filter bag , causing […]…

Operation method of pre-coating filter bag 1、The pre-coating of the filter bag should cut off and stop the ash cleaning system before the combustion or the start of the production process. Open the air inlet valve of the dust collector (including the air inlet and outlet valves of each filter bag chamber). 2、Start the fan […]…